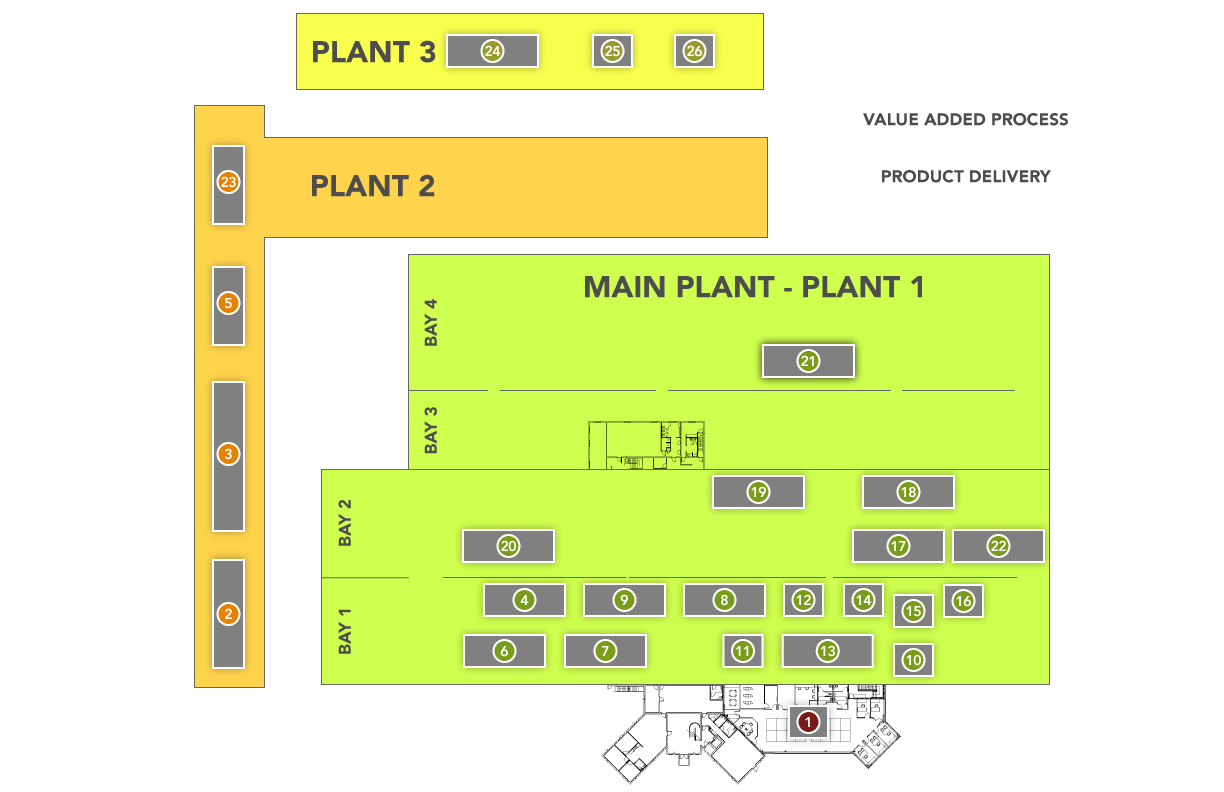

Take an interactive tour of our Large Metal Fabrication and Metal Processing plant located in Waukesha, WI.

Main Plant - Plant 1

Bay 1

- 42,000 Square Feet

- Measuring 80 ft Wide by 525 ft in Length

Overhead Cranes

- Crane Hook Height: 28 ft

- 1—20 TON

- 2—10 TON

- 2—5 TON GANTRY ON RAIL

Jib Cranes

- 10—2 TON

- 3—1 TON

Equipment

- Behringer CNC Band Saw

- Tanaka 12,000 Watt CNC Fiber Plate Laser With 16 Shelf Pallet Stacker and Bevel Head

- Tanaka 6000 Watt CNC Laser Bevel Cutting Machine

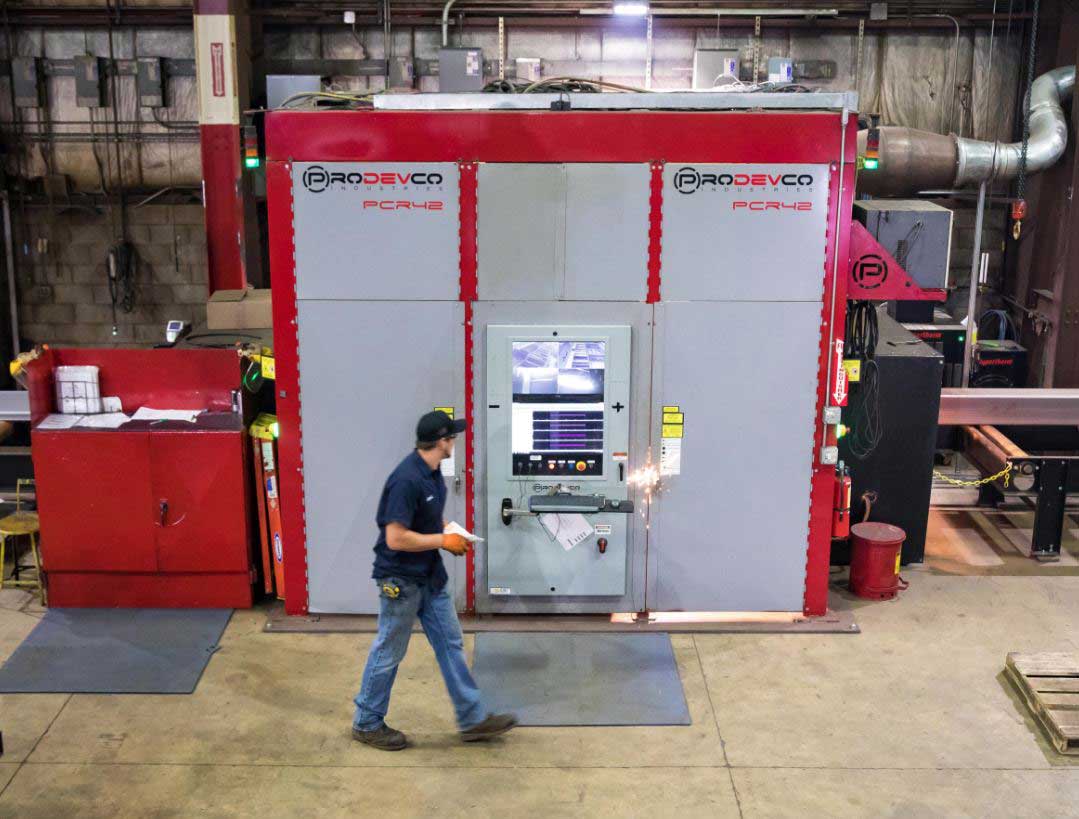

- Prodevco CNC Structural Processor

- Marvel CNC Band Saw

- CNC Plate Roll 5/8”x10’

- 12 Foot Bed CNC Cincinnati 175 Ton Press Brake

- 14 Foot Bed CNC Cincinnati 350 Ton Press Brake

- 30 Foot Bed CNC Pullmax 1375 Ton Press Brake

- Gidding & Lewis CNC VTC 1600 Vertical Turning Center

- YCM TV158 CNC Vertical Machining Center

- Flex CNC Gantry Machining Center

Bay 2

- 42,000 Square Feet

- Measuring 80 ft Wide by 525 ft in Length

Overhead Cranes

- Crane Hook Height: 28 ft

- 1—50 TON w/25 TON AUXILIARY

- 1—20 TON w/10 TON AUXILIARY

- 2—10 TON

Jib Cranes

- 28—2 TON

- 1—1 TON

Bay 3

- 28,500 Square Feet

- Measuring 60 ft Wide by 475 ft in Length

Overhead Cranes

- Crane Hook Height: 41 ft

- 1—50 TON w/ 25 TON AUXILIARY

- 1—20 TON

- 1—10 TON

Jib Cranes

- 10—2 TON

- 1—1 TON

- 3—HALF TON

Bay 4

- 47,500 Square Feet

- Measuring 100 ft Wide by 475 ft in Length

Overhead Cranes

- Crane Hook Height: 46 ft

- 2—100 TON w/ 75 TON AUXILIARY

- 1—20 TON

- 2—20 TON GANTRY ON RAIL

- 6—10 TON GANTRY ON RAIL

Jib Cranes

- 6—2 TON

Plant 2

Two Bays

- Approximately 30,000 Square Feet for Material Receipt and Preparation (60′ x 500′)

- Approximately 30,000 Square Feet for Fit-up, Weld, and Final Assembly (80′ x 375′)

Overhead Cranes

- Crane Hook Height: 25 ft

- 1—20 TON

- 3—10 TON

- 2—5 TON

Jib Cranes

- 7—2 TON

- 7—1 TON

Plant 3

Approximately 24,000 square feet for material receipt, preparation, fit-up weld and final assembly (40′ x 600′)

Overhead Cranes

- Crane Hook Height: 25 feet

- 1-15 TON

- 2-5 TON

Equipment List

- Station 1 – Engineering and Production Control

- Station 2 – Raw Material Receiving, Inspection and Barcoding

- Station 3 – Wheelabrator Plate Blasting Machine

- Station 4 – Behringer CNC Band Saw

- Station 5 – Kinetic K5000 Cutting & Machining Center (Double Gantries)

- Station 6 – Tanaka 12,000 Watt CNC Fiber Plate Laser With 16 Shelf Pallet Stacker and Bevel Head

- Station 7 – Tanaka 6000 Watt CNC Laser Bevel Cutting Machine

- Station 8 – Prodevco CNC Structural Processor

- Station 9 – Marvel CNC Band Saw

- Station 10 – CNC Plate Roll 5/8”x10’

- Station 11 – 12 Foot Bed CNC Cincinnati 175 Ton Press Brake

- Station 12 – 14 Foot Bed CNC Cincinnati 350 Ton Press Brake

- Station 13 – 30 Foot Bed CNC Pullmax 1375 Ton Press Brake

- Station 14 – Giddings & Lewis CNC VTC 1600 Vertical Turning

- Station 15 – YCM TV158 CNC Vertical Machining Center

- Station 16 – Flex CNC Gantry Machining Center

- Station 17 – Toshiba CNC Boring Bar

- Station 18 – FPT CNC Horizontal Machining Center

- Station 19 – Bancroft Positioner/Dual Head Seam Welder

- Station 20 – Ransome Positioner/Dual Head Seam Welder

- Station 21 – Worker Positioner/Dual Head Seam Welder

- Station 22 – SNK CNC Gantry Mill Machining Center

- Station 23 – ABB Beveling and Coping Robot

- Station 24 – Large Rotating Weld Positioner

- Station 25 – Lincohn Robot

- Station 26 – Large Rotating Weld Positioner

Engineering Review & Scheduling

Once a client’s requirement has been reviewed, quoted and a PO has been placed, the information processing begins.

Product Delivery

Weldall currently has trucks capable for local delivery of weldments up to 48,000 lbs and can assist in scheduling shipment per customer directives.

Value Added Process

If a clients’ application requires services outside of Weldall’s core expertise, we have partnered with local experts to be able to include, but not limited to, the following offerings for your Turnkey solution.

- Stress Relief

- Plating

- Fine grinding and polishing

- Final Blasting

- Prime

- Paint

- Specialized crating

- More as required