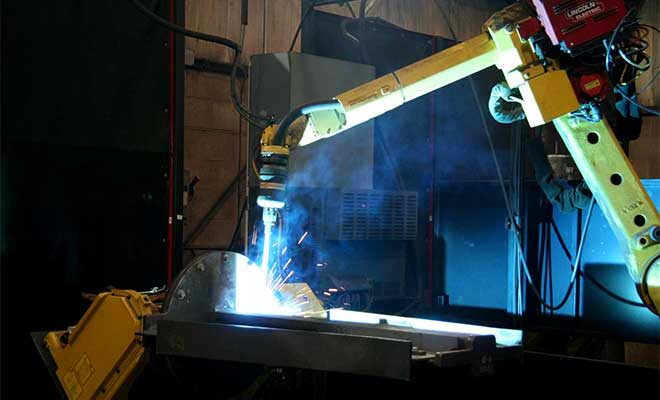

The large variety of applications that Weldall can meet in the welding world require a large variety of processes and equipment to assure the proper results. Weldall has no shortage of capability and is always open to expanding to new processes if a new requirement would be met more efficiently or with higher quality.