Actual Throat: The shortest distance between the weld root and the face of a fillet weld.

Air Carbon Arc Cutting (CAC-A): A cutting process by which metals are melted by the heat of an arc using a carbon electrode. Molten metal is forced away from the cut by a blast of forced air.

Alternating Current (AC): An electrical current that reverses its direction at regular intervals, such as 60 cycles alternating current (AC), or 60 hertz.

Amperage: The measurement of the amount of electricity flowing past a given point in a conductor per second. Current is another name for amperage.

Arc: The physical gap between the end of the electrode and the base metal. The physical gap causes heat due to resistance of current flow and arc rays.

Autogenous: Welds or welding complete without the use of filler materials.

Automatic Welding: Uses equipment which welds without the constant adjusting of controls by the welder or operator. Equipment controls joint alignment by using an automatic sensing device.

AWS: American Welding Society.

AWS D1.1: Structural Steel Welding Code provided by AWS.

CNC Machining: CNC is an acronym or a designation for a machine which uses a dedicated computer to control the actions of the machine and increase its precision. Common CNC machines include Printers, Lathes, and Milling Centers.

Constant Current (CC) Welding Machine: These welding machines have limited maximum short circuit current. They have a negative volt-amp curve and are often referred to as “droopers”.

Constant-Speed Wire Feeder: Feeder operates from 24 or 115 VAC supplied by the welding power source.

Constant Voltage (CV), Constant Potential (CP) Welding Machine: This type of welding machine output maintains a relatively stable, consistent voltage regardless of the amperage output. It results in a relatively flat volt-amp curve.

Current: Another name for amperage. The amount of electricity flowing past a point in a conductor every second.

CWI: AWS Certified Welding Instructor.

Defect: One or more discontinuities that cause a testing failure in a weld.

Dig: Also called Arc Control. Gives a power source variable additional amperage during low voltage (short arc length) conditions while welding. Helps avoid “sticking” Stick electrodes when a short arc length is used.

Direct Current (DC): Flows in one direction and does not reverse its direction of flow as does alternating current.

Direct Current Electrode Negative (DCEN): The direction of current flow through a welding circuit when the electrode lead is connected to the negative terminal and the work lead is connected to the positive terminal of a DC welding machine. Also called direct current, straight polarity (DCSP).

Direct Current Electrode Positive (DCEP): The direction of current flow through a welding circuit when the electrode lead is connected to a positive terminal and the work lead is connected to a negative terminal to a DC welding machine. Also called direct current, reverse polarity (DCRP).

Defect: An interruption in the normal configuration or condition of a material or article under examination that exceeds the applicable code or standard under which the examination is being performed. This term designates rejectability.

Discontinuity: An interruption of the typical structure of a material, such as a lack of homogeneity in its mechanical, metallurgical or physical characteristics. A discontinuity is not necessarily a defect.

Evaluate: To determine worth; the practice of determining if an observed condition exceeds the applicable criteria for the given inspection.

False Indication: An indication caused by incorrect processing, such as fingerprints, smudges, excessive contamination. False indications are those that are eliminated by correcting errors in processing.

Fixed Automation: Automated, electronically controlled welding system for simple, straight or circular welds.

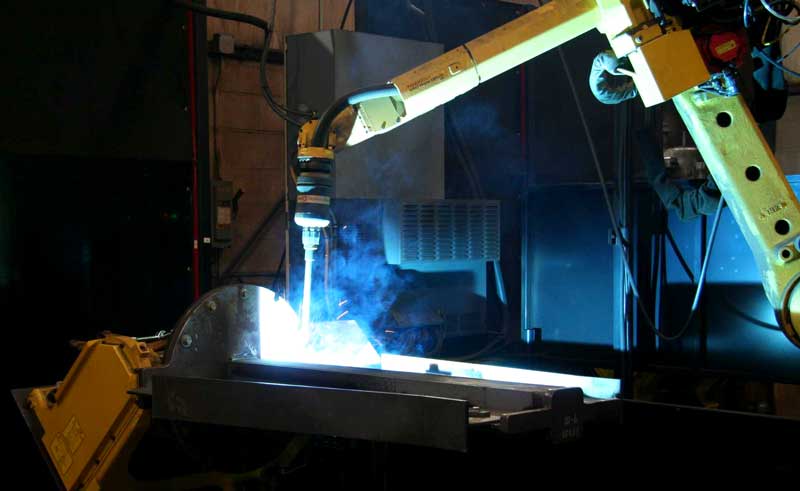

Flexible Automation: Automated, robotically controlled welding system for complex shapes and applications where welding paths require torch-angle manipulation.

Flux Cored Arc Welding (FCAW): An arc welding process which melts and joins metals by heating them with an arc between a continuous, consumable electrode wire and the work. Shielding is obtained from a flux contained within the electrode core. Added shielding may or may not be provided from externally supplied gas or gas mixture.

Gas Metal Arc Welding (GMAW): See MIG Welding.

Gas Tungsten Arc Welding (GTAW): See TIG Welding.

Ground Connection: A safety connection from a welding machine frame to the earth. See Work piece Connection for the difference between work connection and ground connection.

Ground Lead: When referring to the connection from the welding machine to the work, see preferred term Work piece Lead.

Hertz: Hertz is often referred to as “cycles per second”. In the United States, the frequency or directional change of alternating current is usually 60 hertz.

High Frequency: Covers the entire frequency spectrum above 50,000 Hz. Used in TIG welding for arc ignition and stabilization.

Indication: Any area where a suspect condition is observed on the surface of a component under examination. Indications may take various forms, and may be rounded, linear, jagged, smooth, continuous or broken.

Interpretation: To give meaning to; the practice of determining the proper term to associate with an observed condition.

Inverter: Power source which increases the frequency of the incoming primary power, thus providing for a smaller size machine and improved electrical characteristics for welding, such as faster response time and more control for pulse welding.

Large Fabrications: A metal fabrication is the building of metal structures by cutting, bending, and assembling processes. Weldall can cut up to 10 inches (expandable if needed) and execute large or heavy fabrications in excess of 400,000 pounds, working with the heaviest metals available. Stainless Steel, Carbon Steel, Bronze, Aluminum and Monel are just some of the materials we are certified and experienced in working with.

Large Weldments: A weldment is a unit formed by welding together an assembly of pieces. Weldall can cut up to 10 inches (expandable if needed) and execute large or heavy weldments in excess of 400,000 pounds, working with the heaviest metals available. Stainless Steel, Carbon Steel, Bronze, Aluminum and Monel are just some of the materials we are certified and experienced in working with.

Laser Cutting: The use of a highly concentrated beam of light to generate enough heat to pierce and cut. Based on the principle of light amplification by stimulated emission of radiation, laser machines generate waves of light that are consistent in phase, frequency, and direction of travel; the light is described as being correlated, coherent, and collimated. Although the metals industry initially relied on carbon dioxide (CO2) lasers, fiber optic lasers began to gain ground in the middle of the 2000s decade.

Machining: Removing material from a metal part, usually using a cutting tool and power driven machine.

MIG Welding (GMAW or Gas Metal Arc Welding): Also referred to as solid wire welding. An arc welding process which joins metals by heating them with an arc. The arc is between a continuously fed filler metal (consumable) electrode and the work piece. Externally supplied gas or gas mixtures provide shielding.

NDE [Non Destructive Examination]: The process of evaluating the suitability of a component for performance by a method that does not harm the component under examination. (NOTE: In most cases this is considered an indirect method of examination).

NDI [Non Destructive Inspection]: The process of evaluating the suitability of a component for performance by a method that does not harm the component under examination.

NDT [Non Destructive Testing]: The process of evaluating the suitability of a component for performance by a method that does not harm the component under examination.

Non-relevant Indication: This may be argued, but in my opinion, an indication due to the normal aspects of a component under evaluation. This could be geometry, threads, splines, press-fit plugs, surface roughness, and press fit assemblies. For this study guide, an indication caused by an acceptable discontinuity will just be considered an acceptable discontinuity, and not non-relevant, to eliminate confusion.

Plasma Arc Cutting: An arc cutting process which severs metal by using a constricted arc to melt a small area of the work. This process can cut all metals that conduct electricity.

Prototype Manufacturing: The process of manufacturing a newly designed part or machine that has not been made in the past. This may range from an upgraded size of an existing design, to a design that incorporates expanded capabilities of the new part or machine is capable of achieving, to a completely new design that is meant to accomplish something that has never been achieved before. This type of manufacturing requires extreme flexibility and ingenuity to overcome the challenges of taking a theoretical design on “paper” through many iterations or “engineering changes” required to make the part or machine more easily manufactured, or in some cases, physically possible to manufacture at all in the real world.

Pulsed MIG (MIG-P): A modified spray transfer process that produces no spatter because the wire does not touch the weld puddle. Applications best suited for pulsed MIG are those currently using the short circuit transfer method for welding steel, 14 gauge (1.8 mm) and up.

Pulsed TIG (TIG-P): A modified TIG process appropriate for welding thinner materials.

Pulsing: Sequencing and controlling the amount of current, the frequency, and the duration of the welding arc.

Qualitative Examination: Of quality. This examination may lead to results based on judgment or opinion and may not be based on a measurable quantity.

Quantitative Examination: Determined through measurement or reproducible, quantity. An example would be a measurement taken with micrometers or calipers.

Rated Load: The amperage and voltage the power source is designed to produce for a given specific duty cycle period. For example, 300 amps, 32 load volts, at 60% duty cycle.

RMS (Root Mean Square): The “effective” values of measured AC voltage or amperage. RMS equals 0.707 times the maximum, or peak value.

Semiautomatic Welding: The equipment controls only the electrode wire feeding. The welding gun movement is controlled by hand.

Shielded Metal Arc Welding: See Stick Welding.

Shielding Gas: Protective gas used to prevent atmospheric contamination of the weld pool.

Single-Phase Circuit: An electrical circuit producing only one alternating cycle within a 360 degree time span.

Spatter: The metal particles blown away from the welding arc. These particles do not become part of the completed weld.

Spot Welding: Usually made on materials having some type of overlapping joint design. Can refer to resistance, MIG or TIG spot welding. Resistance spot welds are made from electrodes on both sides of the joint, while TIG and MIG spots are made from one side only.

Squarewave™: The AC output of a power source that has the ability to rapidly switch between the positive and negative half cycles of alternating current.

Stick Welding (SMAW or Shielded Metal Arc): An arc welding process which melts and joins metals by heating them with an arc, between a covered metal electrode and the work. Shielding gas is obtained from the electrode outer coating, often called flux. Filler metal is primarily obtained from the electrode core.

Stud Welding: A technique similar to flash welding where a fastener or specially formed nut is welded onto another metal part, typically a base metal or substrate.

Submerged Arc Welding (SAW): A process by which metals are joined by an arc or arcs between a bare metal electrode or electrodes and the work. Shielding is supplied by a granular, fusible material usually brought to the work from a flux hopper. Typically provides deeper base metal penetration and fusion.

Three-Phase Circuit: An electrical circuit delivering three cycles within a 360 degree time span, and the cycles are 120 electrical degrees apart.

Tungsten Inert Gas (TIG) Welding: A welding method where an electric arc is maintained between a non-consumable tungsten electrode and the part to be welded. The TIG or GTAW torch feeds inert gas, such as Argon or Helium, to serve as a barrier between the weld and contaminants that may be present in the surrounding air.

Torch: A device used in the TIG (GTAW) process to control the position of the electrode, to transfer current to the arc, and to direct the flow of the shielding gas.

Touch Start: A low-voltage, low-amperage arc starting procedure for TIG (GTAW). The tungsten is touched to the work piece; when the tungsten is lifted from the work piece an arc is established.

Tungsten: Rare metallic element with extremely high melting point (3410° Celsius). Used in manufacturing TIG electrodes.

Turn Key Assembly: The process of including additional assembly or process to the scope of typically accepted work to reduce the steps or work required by the end customer to achieve their final and completed requirement; i.e., Providing the assembly of several fully machined and painted components into a completed machine with electrical and/or power requirement vs. just providing loose parts/weldment for the end customer to assemble.

Value Added Assembly: See Turn Key Assembly.

Weld Metal: The electrode and base metal that was melted while welding was taking place. This forms the welding bead.

Weld Transfer: Method by which metal is transferred from the wire to the molten puddle.

Wet-Stacking: Unburned fuel and engine oil collecting in the exhaust stack of a diesel engine, characterized by the exhaust stack being coated with a black, sticky, oily substance. The condition is caused by the engine being run at too light of a load for extended periods of time. Caught early, this does not cause permanent damage and can be alleviated if additional load is applied. If ignored, permanent damage can occur to the cylinder walls and piston rings. Improved emission standards and higher quality fuel make engines less prone to wet-stacking in recent years.

ADDENDUM [More Specific to “Quality”]

Electromagnetic Testing (ET) or Eddy Current Testing: Electrical currents are generated in a conductive material by an induced alternating magnetic field. The electrical currents are called eddy currents because they flow in circles at and just below the surface of the material. Interruptions in the flow of eddy currents, caused by imperfections, dimensional changes, or changes in the material’s conductive and permeability properties, can be detected with the proper equipment.

Leak Testing (LT): Several techniques are used to detect and locate leaks in pressure containment parts, pressure vessels, and structures. Leaks can be detected by using electronic listening devices, pressure gauge measurements, liquid and gas penetrant techniques, and/or a simple soap-bubble test

Magnetic Particle Testing (MT): This NDE method is accomplished by inducing a magnetic field in a ferromagnetic material and then dusting the surface with iron particles (either dry or suspended in liquid). Surface and near-surface imperfections distort the magnetic field and concentrate iron particles near imperfections, previewing a visual indication of the flaw

NDT/NDE Methods: The number of NDT methods that can be used to inspect components and make measurements is large and continues to grow. Researchers continue to find new ways of applying physics and other scientific disciplines to develop better NDT methods. However, there are six NDT methods that are used most often. These methods are visual inspection, penetrant testing, magnetic particle testing, electromagnetic or eddy current testing, radiography, and ultrasonic testing. These methods and a few others are briefly described below.

Penetrant Testing (PT): Test objects are coated with visible or fluorescent dye solution. Excess dye is then removed from the surface, and a developer is applied. The developer acts as blotter, drawing trapped penetrant out of imperfections open to the surface. With visible dyes, vivid color contrasts between the penetrant and developer make “bleedout” easy to see. With fluorescent dyes, ultraviolet light is used to make the bleedout fluoresce brightly, thus allowing imperfections to be readily seen.

Radiography (RT): Radiography involves the use of penetrating gamma or X-radiation to examine parts and products for imperfections. An X-ray generator or radioactive isotope is used as a source of radiation. Radiation is directed through a part and onto film or other imaging media. The resulting shadowgraph shows the dimensional features of the part. Possible imperfections are indicated as density changes on the film in the same manner as a medical X-ray shows broken bones.

Ultrasonic Testing (UT): Ultrasonics use transmission of high-frequency sound waves into a material to detect imperfections or to locate changes in material properties. The most commonly used ultrasonic testing technique is pulse echo, wherein sound is introduced into a test object and reflections (echoes) are returned to a receiver from internal imperfections or from the part’s geometrical surfaces.

Visual and Optical Testing (VT): Visual inspection involves using an inspector’s eyes to look for defects. The inspector may also use special tools such as magnifying glasses, mirrors, or borescopes to gain access and more closely inspect the subject area. Visual examiners follow procedures that range from simple to very complex.